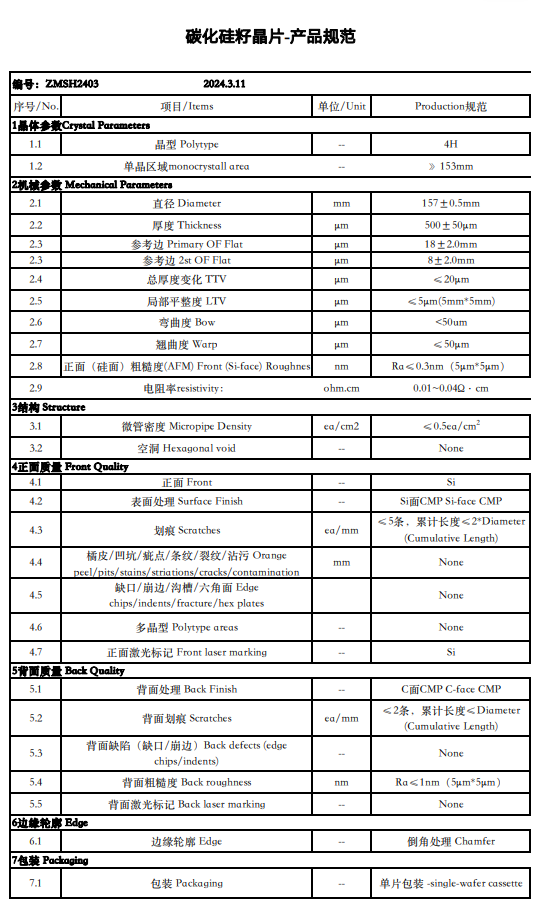

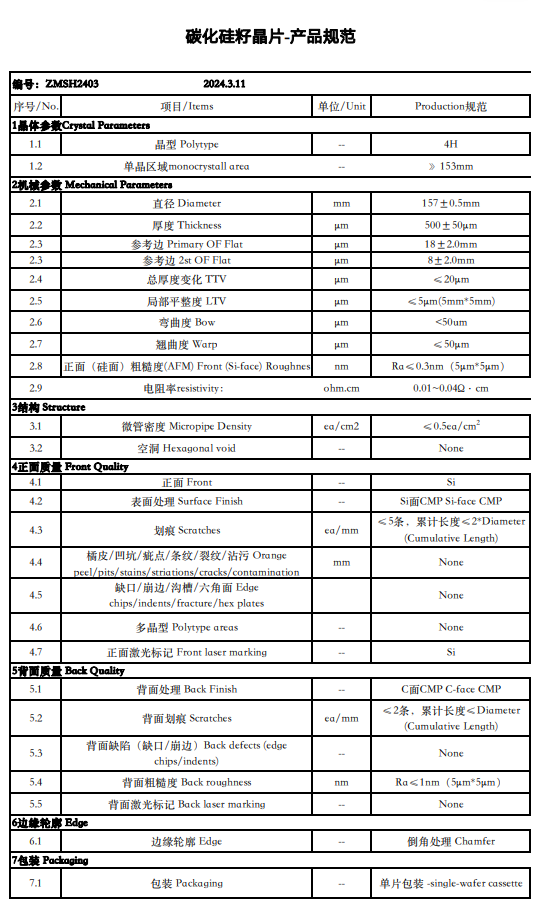

Silicon Carbide Seed wafer type 4H Dia 157±0.5mm thickness 500±50um

monocrystall area >153mm

4H Silicon Carbide Seed's abstract

In the field of silicon carbide (SiC) crystal growth,

production-grade SiC seed wafers are essential for creating

high-performance crystals. These wafers act as the starting

material for single-crystal SiC growth, used in high-temperature,

high-power electronic devices. Production-grade wafers must meet

strict criteria for surface uniformity, purity, and defect levels

to support the growth of defect-minimized SiC crystals. The use of

seed wafers ensures consistent crystal structures and is crucial in

power semiconductor devices like diodes and transistors.

High-quality seed wafers contribute to the efficiency and

durability of SiC components in various industries.

4H Silicon Carbide Seed's photo

4H Silicon Carbide Seed's properties

SiC seed wafers are specifically designed to withstand the high

temperatures required for SiC crysta growth. Processes

such as physical vapor transport (PVT) rely on temperatures

exceeding 2000°C, and the seed wafer must remain stable under these

extreme conditions. Production-grade wafers are engineered to have

exceptional thermal stability, which allows for consistent and

reliable crystal growth. This temperature resilience is crucial for

growing large, defect-free SiC crystals that are used in high-power

and high-temperature applications, such as electric vehicles,

aerospace systems, and renewable energy technologies. Wafers

optimized for high-temperature growth help reduce defects like

dislocations and micropipes, ensuring a higher yield of usable SiC

material.

4H Silicon Carbide Seed's applications

- Power Electronics

4H-SiC seed wafers are extensively used for growing SiC crystals

for high-performance power electronics. Devices made from 4H-SiC,

such as MOSFETs, Schottky diodes, and IGBTs, offer high energy

efficiency, lower switching losses, and the ability to operate at

high voltages and temperatures. These characteristics make them

ideal for applications in electric vehicles (EVs), renewable energy

systems (such as solar inverters and wind turbines), and industrial

power converters. 4H-SiC-based components improve overall energy

efficiency and durability, making them highly sought after in

modern power systems.

- High-Temperature and Harsh Environments

4H-SiC’s wide bandgap, high breakdown voltage, and excellent

thermal conductivity make it perfect for devices operating in

extreme environments. Applications such as aerospace systems, oil

and gas exploration, and military equipment benefit from

4H-SiC-based semiconductors because they can withstand high

temperatures, radiation, and harsh chemical exposure while

maintaining stable performance. Sensors, actuators, and other

electronic devices in these industries often rely on 4H-SiC

components for reliable operations.

- High-Frequency and RF Devices

4H-SiC seed wafers are used in the fabrication of high-frequency

and RF (radio frequency) devices. Due to its low loss at high

frequencies and high electron mobility, 4H-SiC is preferred for

high-frequency communication systems, radar, and satellite

communications. Devices built with 4H-SiC offer high efficiency and

lower power consumption, making them essential in telecommunication

infrastructure, aerospace, and defense industries where performance

and reliability are critical.

- LEDs and Optoelectronics

4H-SiC serves as a substrate for growing gallium nitride (GaN)

crystals, which are used in blue and ultraviolet (UV) LEDs and

laser diodes. These devices are essential in applications like

solid-state lighting, automotive lighting, and display

technologies. The high thermal conductivity and mechanical strength

of 4H-SiC provide a stable platform for GaN devices, enhancing

their efficiency and lifespan.

Specification