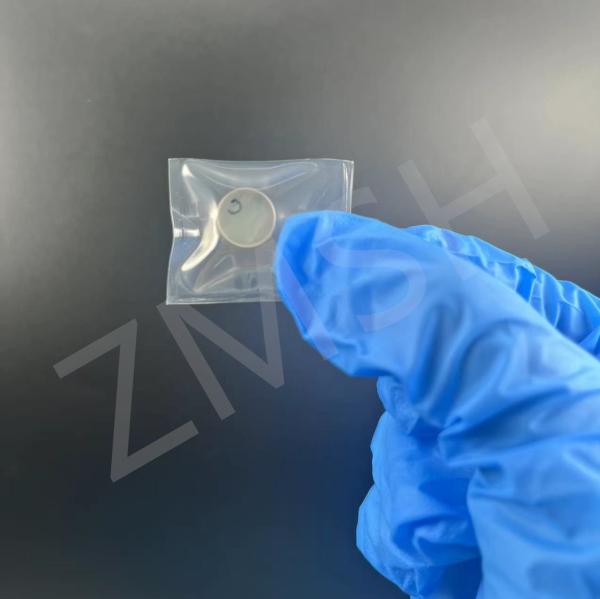

SiC Wafer, Silicon Carbide Wafer, SiC Substrate, Silicon Carbide

Substrate, Prime Grade, Dummy Grade, 2inch SiC, 4inch SiC, 6inch

SiC, 8inch SiC, 12inch SiC, 4H-N, 4H-SEMI, 6H-N, HPSI type,

Customization SiC Substrate

About 4H-SEMI SiC

- support customized ones with design artwork

- a hexagonal crystal (4H SiC), made by SiC monocrystal

- High hardness, up to 9.2 Mohs, second only to diamond.

- excellent thermal conductivity, suitable for high-temperature

environments.

- wide bandgap characteristics, suitable for high-frequency,

high-power electronic devices.

Description of 4H-SEMI SiC

4H-Semi SiC wafers refer to 4H-semi-insulating silicon carbide

(SiC) wafers.

Such wafers are usually made by cutting and processing high-purity

4H-SiC crystals.

4H-SiC is a SiC crystal with a specific crystal structure, in which

silicon (Si) atoms and carbon (C) atoms are arranged in a specific

way to form a lattice structure.

4H-SiC wafers have attracted much attention due to their importance

in the semiconductor industry.

4H-SiC has a wide range of applications in power electronics, RF

and microwave devices, optoelectronic devices, and high-temperature

and high-pressure applications.

Semi-insulating 4H-SiC wafers generally exhibit low carrier

concentrations and high insulation properties, and are suitable for

many high-power, high-frequency, and high-temperature applications.

These 4H-Semi SiC wafers are often used to manufacture various

types of devices, such as power MOSFETs, power diodes, RF power

amplifiers, photoelectric sensors, etc.

Their excellent performance, high voltage resistance, high thermal

conductivity, and stability at high temperatures and high pressures

make these wafers play a key role in various industrial and

scientific research applications.

Details of 4H-SiC

Each type of SiC wafer has its own physical details.

| SUBSTRATE PROPERTY | Production Grade | Dummy Grade |

| Diameter | 10mm |

| Surface Orientation | on-axis: {0001} ± 0.2° for SEMI type; |

| off-axis: 4° toward <11-20> ± 0.5° for N type |

| Primary Flat Orientation | <11-20> ± 5.0˚ |

| Secondary Flat Orientation | 90.0˚ CW from Primary ± 5.0˚, silicon face up |

| Primary Flat Length | 16.0 mm ± 1.65 mm |

| Secondary Flat Length | 8.0 mm ± 1.65 mm |

| Wafer Edge | Chamfer |

| Micropipe Density | ≤5 micropipes/cm2 | ≤50 micropipes/cm2 |

| Polytype Areas by High-Intensity Light | None permitted | ≤10% area |

| Resistivity | 0.015~0.028Ω·cm | (area 75%) |

| 0.015~0.028Ω·cm |

| Thickness | 5mm |

| TTV | ≤10 μm | ≤15 μm |

| BOW | ≤10 μm | ≤15 μm |

| Warp | ≤25 μm |

| Surface Finish | Double Side Polish, Si Face CMP (chemical polishing) |

| Surface Roughness | CMP Si Face Ra≤0.5 nm | N/A |

| Cracks by High-Intensity Light | None permitted |

| Edge Chips/Indents by Diffuse Lighting | None permitted | Qty.2 <1.0 mm width and depth |

| Total Usable Area | ≥90% | N/A |

| Note: Customized specifications other than the above parameters are

acceptable. |

Other samples of 4H SiC

*Please feel free to contact us if you have further customized

requirements

Products Recommend

1.4inch 3C

N-type SiC Substrate Silicon Carbide Substrate Thick 350um Prime

grade Dummy grade

2.4Inch

4H-N Silicon Carbide SiC Substrate Dia 100mm N type Prime Grade

Dummy Grade Thickness 350um Customized

About us

Our enterprise, ZMSH, specialises in the research, production,

processing, and sales of Semiconductor substrates and optical

crystal materials.

We have an experienced engineering team, management expertise,

precision processing equipment, and testing instruments, providing

us with extremely strong capabilities in processing non-standard

products.

We can research, develop, and design various new products according

to customer needs.

The company will adhere to the principle of "customer-centred,

quality-based" and strive to become a top-tier high-tech enterprise

in the field of optoelectronic materials.

FAQ

1. Q: What is the manufacturing process of 4H-Semi SiC cutting

blades?

A: Manufacturing 4H-semi-insulating silicon carbide (SiC) cutting

blades requires a series of complex process steps, including

crystal growth, cutting, grinding and polishing.

2. Q: What is the future prospect of 4H-SEMI SiC

A: They look promising due to its unique properties and the

increasing demand for high-performance semiconductor materials in

various industries