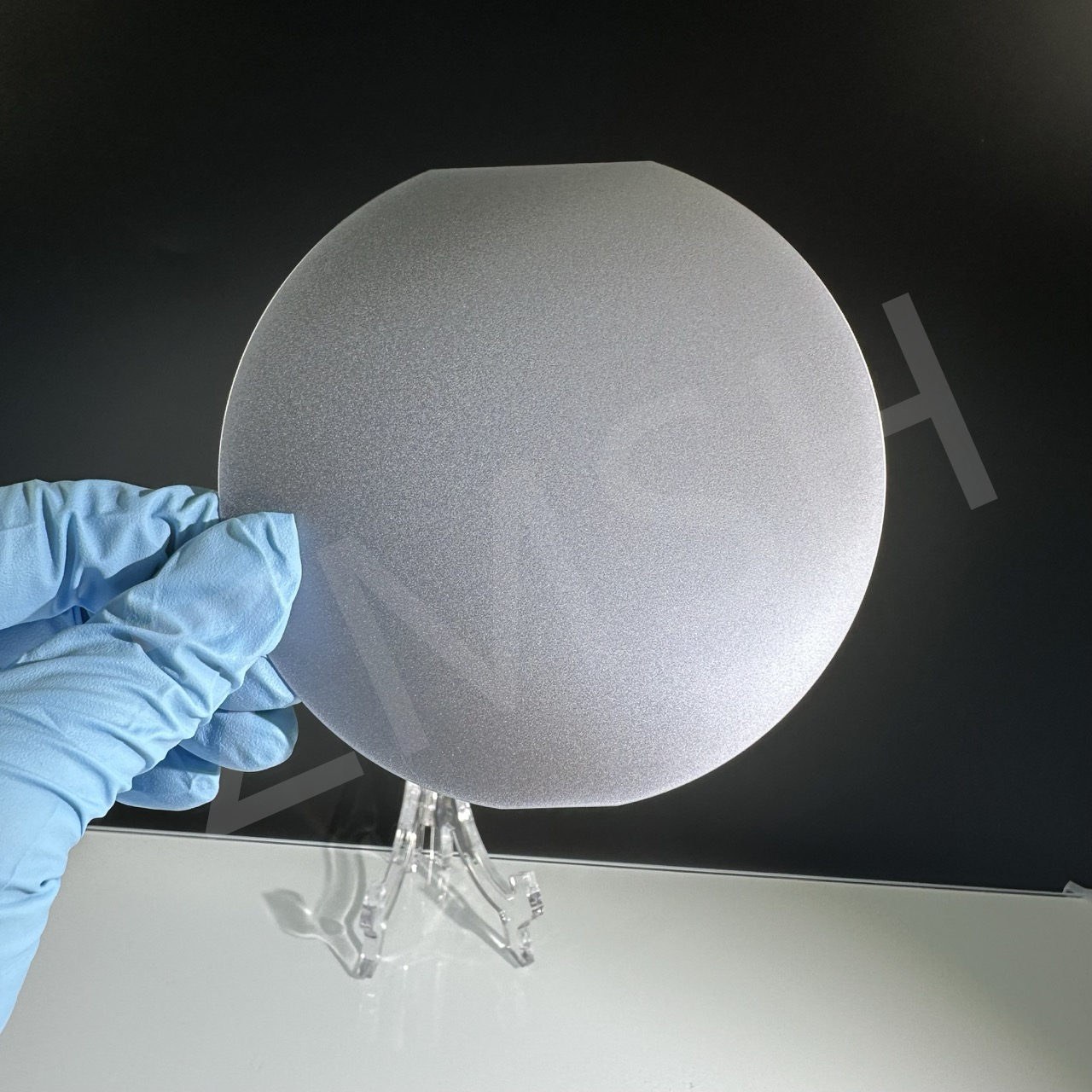

Semi-insulating SiC on Si Compound Wafer , Si wafer, Silicon Wafer,

Compound Wafer, SiC on Si Compound Substrate, Silicon Carbide

Substrate, P Grade, D Grade, 4inch, 6inch, 4H-SEMI

About Compound wafer

- use SiC on Si compound wafer to manufacture

- support customized ones with design artwork

- high-quality, suitable for high-performance applications

- high hardness and durability, high thermal conductivity

- widely used in high-voltage and high-frequency devices, RF devices,

etc.

More of Compound wafer

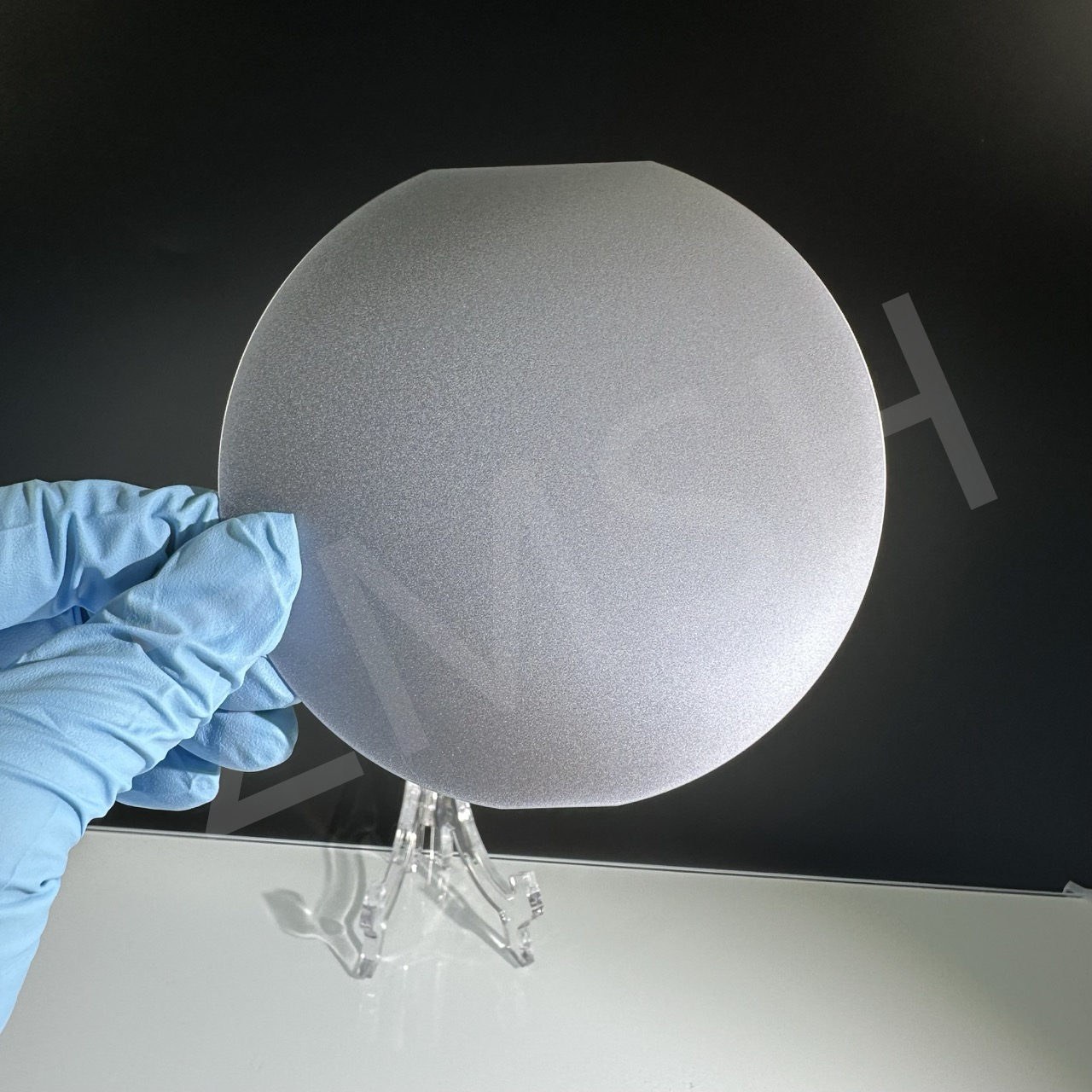

Semi-insulating SiC on Si Compound Wafer is a high-performance

advanced semiconductor material.

It has the advantages of both silicon substrate and semi-insulating

silicon carbide substrate.

It has excellent thermal conductivity and outstanding high

mechanical strength.

It can significantly reduce low leakage current under high

temperature and high-frequency conditions and effectively improve

device performance.

It is an excellent semiconductor material.

It is usually used in power electronics, radio frequency, and

optoelectronic devices, especially in high-demand applications

requiring excellent heat dissipation and electrical stability.

Although its production cost is relatively high compared to silicon

wafers and silicon carbide wafers, it has attracted more and more

attention and favour in high-performance technology due to its

advantages in improving device efficiency and stability

reliability.

Therefore, semi-insulating SiC on Si composite wafers has broad

development prospects in future high-end technology applications.

Details of Compound wafer

| Item | Specification |

| Diameter | 150 ± 0.2 mm |

| SiC Polytype | 4H |

| SiC Resistivity | ≥1E8 Ω·cm |

| Transfer SiC layer Thickness | ≥0.1 μm |

| Void | ≤5 ea/wafer (2 mm > D > 0.5 mm) |

| Front roughness | Ra ≤ 0.2 nm (5 μm × 5 μm) |

| Si Orientation | <111>/<100>/<110> |

| Si Type | P/N |

| Flat/Notch | Flat/Notch |

| Edge Chip, Scratch, Crack (visual inspection) | None |

| TTV | ≤5 μm |

| Thickness | 500/625/675 ± 25 μm |

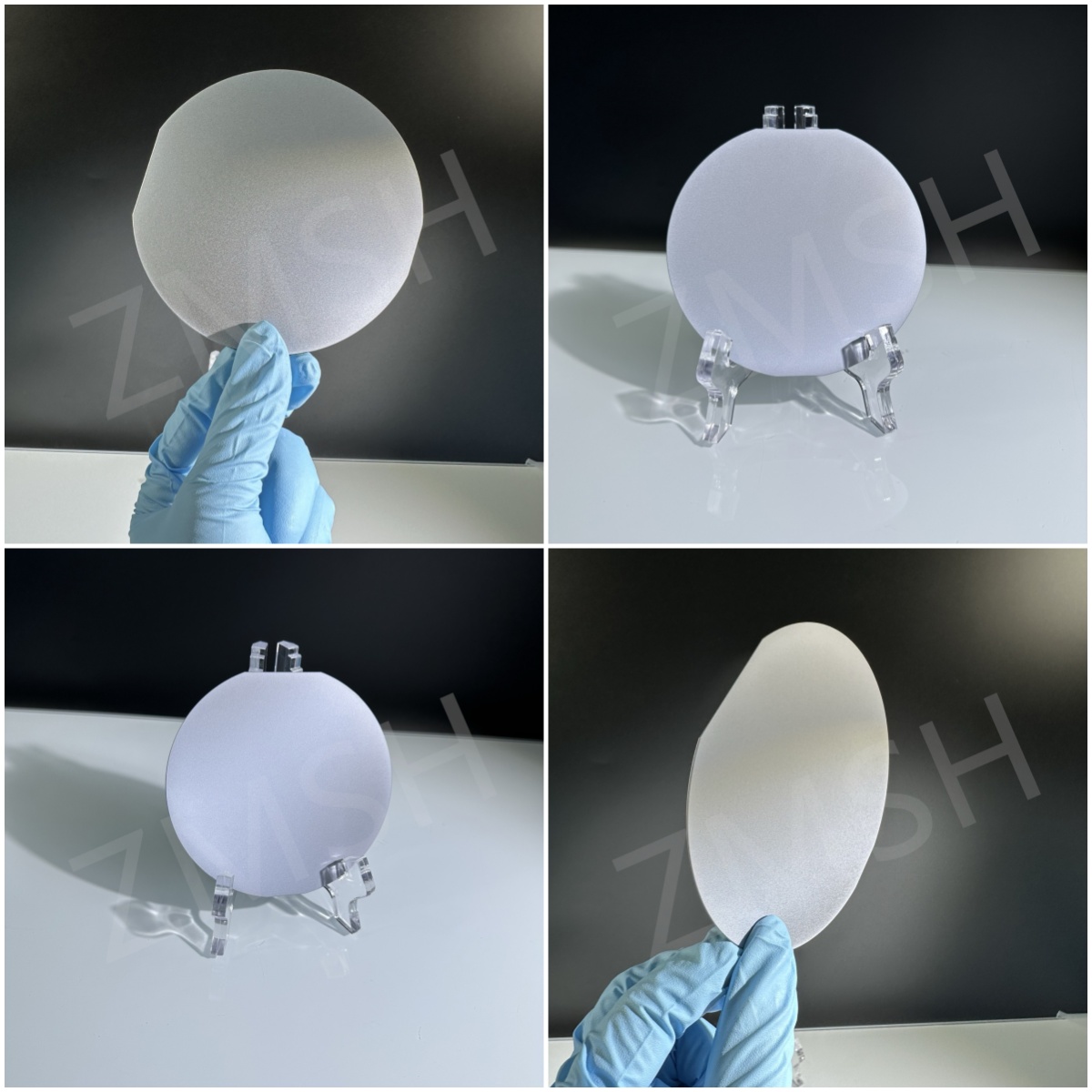

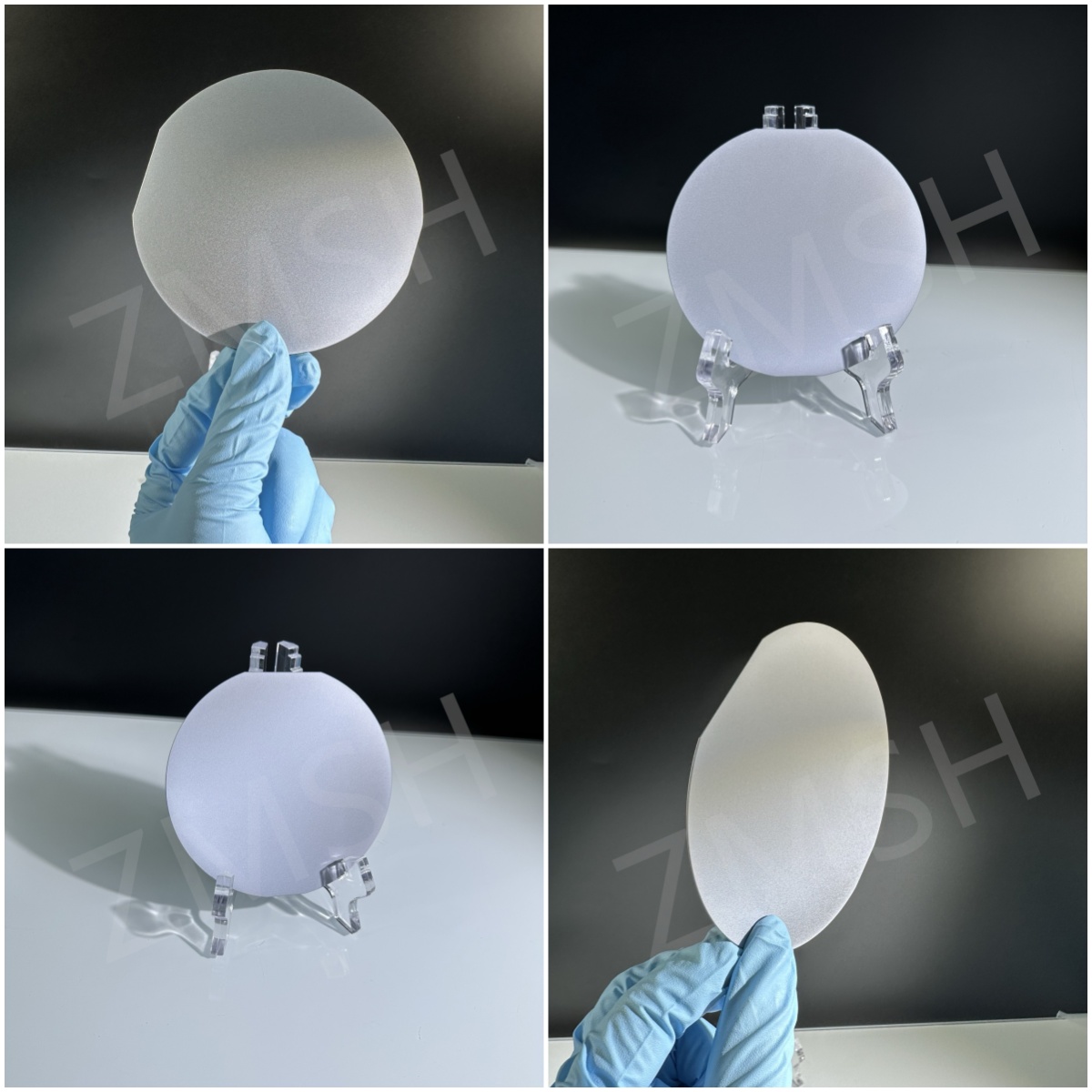

Other pictures of Compound wafer

*Please feel free to contact us if you have customized demands.

About us

Our enterprise, ZMSH, specialises in the research, production,

processing, and sales of Semiconductor substrates and optical

crystal materials.

We have an experienced engineering team, management expertise,

precision processing equipment, and testing instruments, providing

us with extremely strong capabilities in processing non-standard

products.

We can research, develop, and design various new products according

to customer needs.

The company will adhere to the principle of "customer-centred,

quality-based" and strive to become a top-tier high-tech enterprise

in the field of optoelectronic materials.

Similar product recommendations

1.

4H-SEMI Silicon Carbide SiC

Substrate 2 Inch Thickness 350um 500um P Grade D Grade SiC

Wafer

2. 2"

3" FZ SiO2 Single Crystal IC Chips 100um 200um Dry Wet Oxidation

Layer 100nm 300nm

FAQ

1. Q: What is the common surface orientation of SiC on Si wafers?

A: The common orientation is (111) for SiC, aligned with the

silicon substrate.

2. Q: Are there specific annealing requirements for SiC on Si

wafers?

A: Yes, high-temperature annealing is often required to improve

material properties and reduce defects.