Abstract

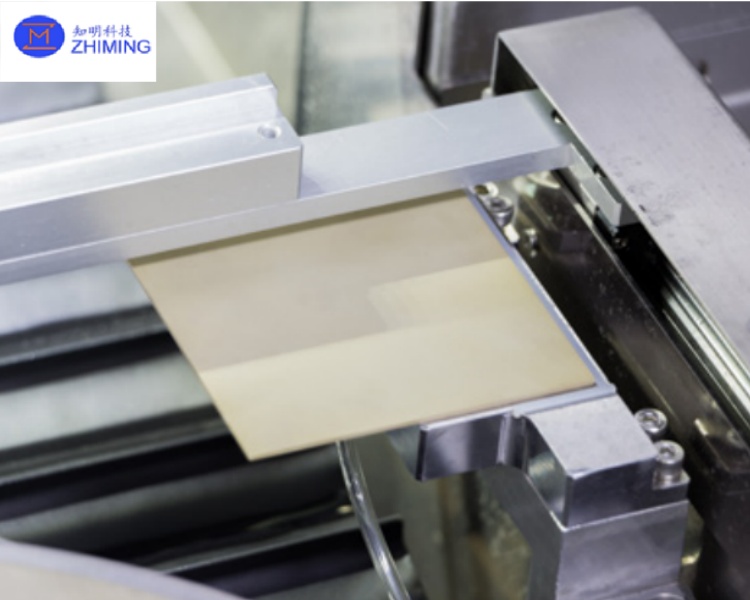

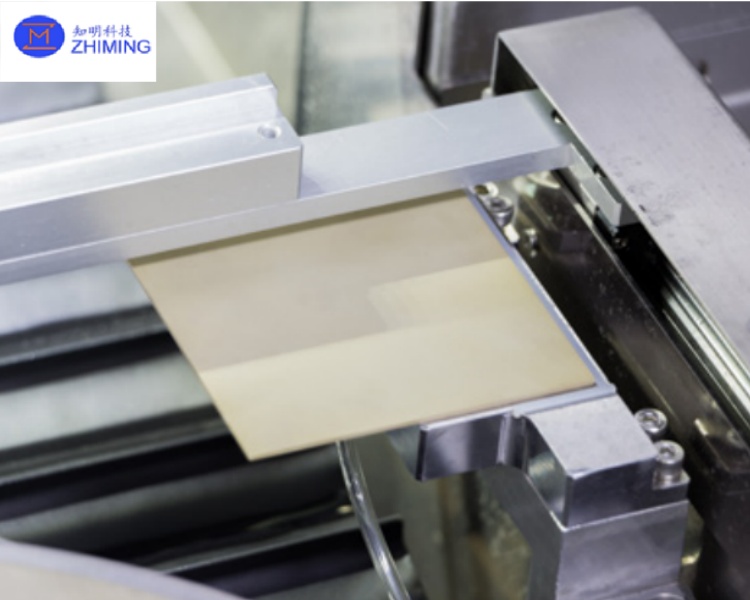

Fully Automatic Precision Dicing Saw equipment for 8inch 12inch

Wafer Cutting

The fully automatic precision dicing saw is an advanced

semiconductor cutting system designed for high-precision separation

of wafers (8"/12") and brittle materials. Utilizing diamond blade

technology (30,000-60,000 RPM), it achieves micron-level cutting

accuracy (±2μm) with minimal chipping (<5μm), outperforming

alternative methods in semiconductor and advanced packaging

applications. The system integrates high-rigidity spindles,

nanometric positioning stages, and intelligent vision alignment for

unmanned operation, meeting the stringent requirements of modern

chip manufacturing and third-generation semiconductor processing.

Technical parameters

| Parameter | Specification |

| Working Size | Φ8", Φ12" |

| Spindle | Dual-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Blade Size | 2" ~ 3" |

| Y1 / Y2 Axis | Single-step increment: 0.0001 mm |

| Positioning accuracy: < 0.002 mm |

| Cutting range: 310 mm |

| X Axis | Feed speed range: 0.1–600 mm/s |

| Z1 / Z2 Axis | Single-step increment: 0.0001 mm |

| Positioning accuracy: ≤ 0.001 mm |

| θ Axis | Positioning accuracy: ±15" |

| Cleaning Station | Rotation speed: 100–3000 rpm |

| Cleaning method: Auto rinse & spin-dry |

| Operating Voltage | 3-phase 380V 50Hz |

| Dimensions (W×D×H) | 1550×1255×1880 mm |

| Weight | 2100 kg |

Advantages

1. High-speed cassette frame scanning with collision prevention

alert system enables rapid precision positioning and superior error

correction capability;

2. Innovative dual-spindle synchronous cutting mode increases

processing efficiency by 80% compared to single-spindle systems;

3. Premium imported ball screws, linear guides, and Y-axis grating

closed-loop control ensure long-term machining stability;

4. Fully automated operation

(loading/positioning/cutting/inspection) significantly reduces

manual intervention;

5. Unique gantry-style dual-spindle design with minimum 24mm blade

spacing accommodates diverse cutting requirements;

Features

1. High-precision non-contact height measurement system;

2. Multi-wafer simultaneous dual-blade cutting capability;

3. Intelligent detection systems (auto-calibration/cut mark

inspection/blade breakage monitoring);

4. Multi-mode alignment algorithms adaptable to various process

requirements;

5. Real-time position monitoring with automatic error correction;

6. First-cut quality verification mechanism;

7. Customizable factory automation module integration;

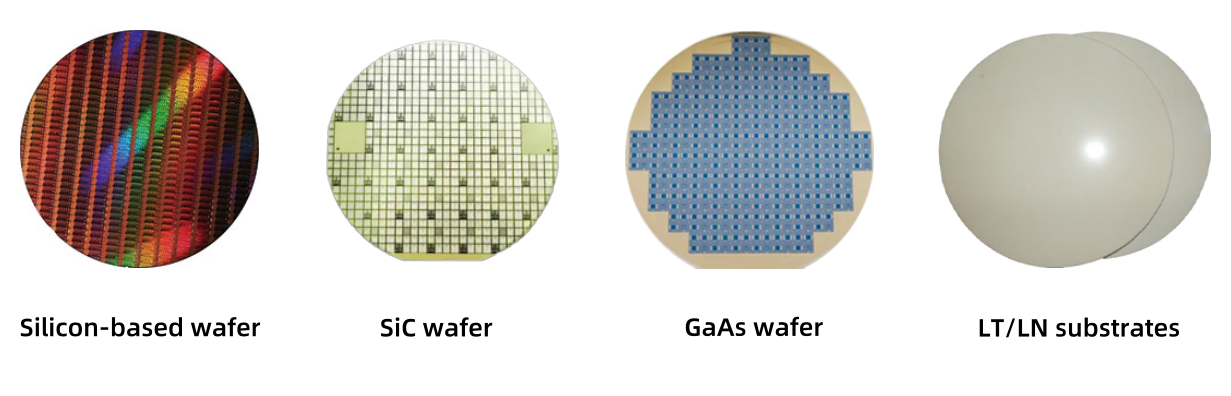

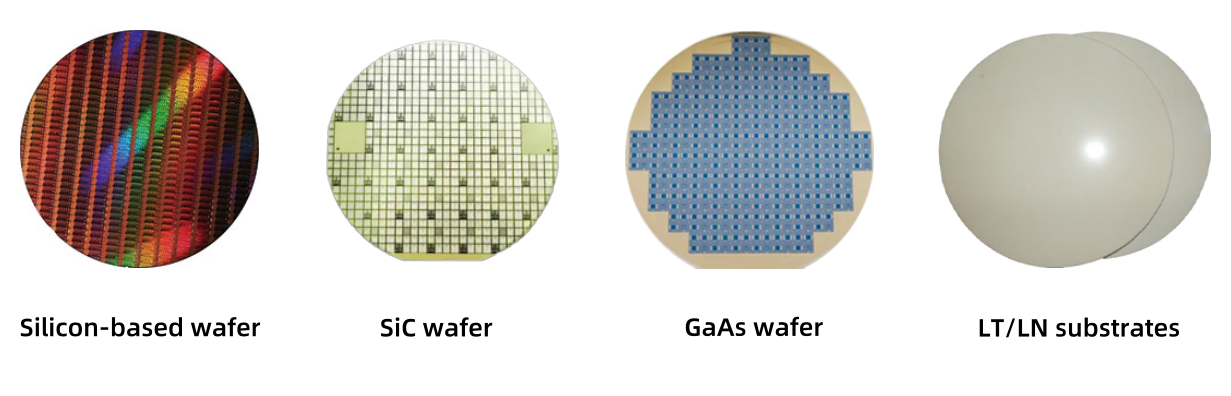

Adaptation materials and applications

| Material | Typical Applications | Processing Requirements |

| Aluminum Nitride (AlN) | High-power thermal substrates, LED packaging | Low-stress dicing, delamination prevention |

| PZT Ceramic | 5G filters, SAW devices | High-frequency stability cutting |

| Bismuth Telluride (Bi₂Te₃) | Thermoelectric modules | Low-temperature processing |

| Monocrystalline Silicon (Si) | IC chips | Submicron dicing accuracy |

| Epoxy Molding Compound | BGA substrates | Multilayer material compatibility |

| Cu Pillars/PI Dielectric | WLCSP | Ultra-thin wafer processing |

Machining effect