Abstract

Infrared Picosecond Dual-Platform Laser Cutting System for

Sapphire/Quartz/Optical Glass Processing

The infrared picosecond dual-platform glass laser cutting system is

a high-end precision machining solution based on ultrafast laser

technology. It utilizes a 1064nm infrared picosecond laser (pulse

width 1-10ps) combined with a dual-station platform design,

specifically engineered for precision processing of high-hardness

brittle materials including sapphire, quartz glass, and optical

glass.

Through a "cold processing" mechanism based on multiphoton

absorption, the system achieves high-quality cutting with a

heat-affected zone <1μm and surface roughness Ra<0.5μm, while

maintaining ±2μm machining accuracy and 10μm minimum feature size

capability. The dual-platform configuration enables alternating

loading/unloading operations, improving processing efficiency by

over 30% with cutting speeds reaching 100-500mm/s - making it

particularly suitable for mass production of premium components

like smartwatch covers, optical lenses, and semiconductor wafers.

Main parameter

| Laser Type | Infrared Picosecond |

| Platform Size | 700×1200 (mm) |

| 900×1400 (mm) |

| Cutting Thickness | 0.03-80 (mm) |

| Cutting Speed | 0-1000 (mm/s) |

| Cutting Edge Breakage | <0.01 (mm) |

| Note: Platform size can be customized. |

Working Principle

1. Ultrafast Laser Interaction Mechanism

Utilizing picosecond-level ultra-short pulse lasers (10^-12 second

level) with extremely high peak power density (GW/cm² level) to

instantaneously plasmaize materials, achieving atomic-level

material removal.

2. Nonlinear Absorption Effect

Laser energy is captured by materials through multiphoton

absorption processes, overcoming traditional linear absorption

limitations to enable effective processing of transparent

materials.

3. Dual-Station Collaborative Operation

Two independent processing platforms achieve parallel machining and

loading/unloading operations through an intelligent scheduling

system, maximizing equipment utilization efficiency.

Advantages

1. High degree of overall automation (cutting and breaking can be

integrated), low power consumption, and simple operation.

2. The non-contact nature of laser processing enables techniques

unachievable by traditional methods.

3. Consumable-free processing with lower operational costs and

enhanced environmental friendliness.

4. High precision, zero taper, and no secondary damage to

workpieces.

Process Applications

Suitable for precision cutting of various hard and brittle

materials, including:

· Contour machining of standard/optical glass

· Cutting of ultra-hard materials (quartz, sapphire)

· Profile processing of tempered glass, filters, and mirrors

· Precise internal hole extraction

Processing Advantages

· Dual-platform integrated cutting/breaking with flexible switching;

· High-speed processing of complex profiles (30%+ efficiency

improvement);

· Taper-free cuts with smooth, burr-free edges;

· Fully automatic model changeover with intuitive operation;

· Zero consumables, pollution-free (50% lower operating costs);

· No machining waste generation, ensuring surface integrity;

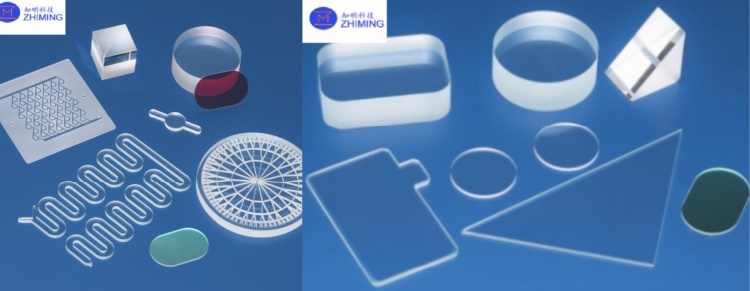

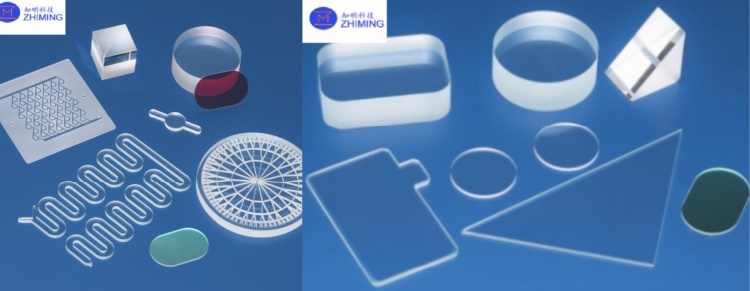

Machining effect——Sample display