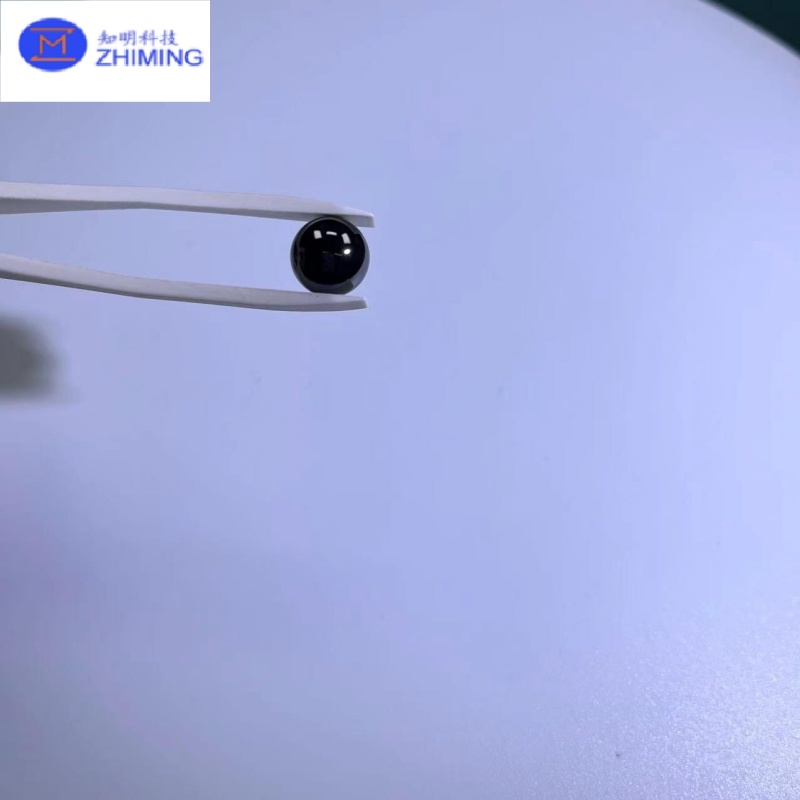

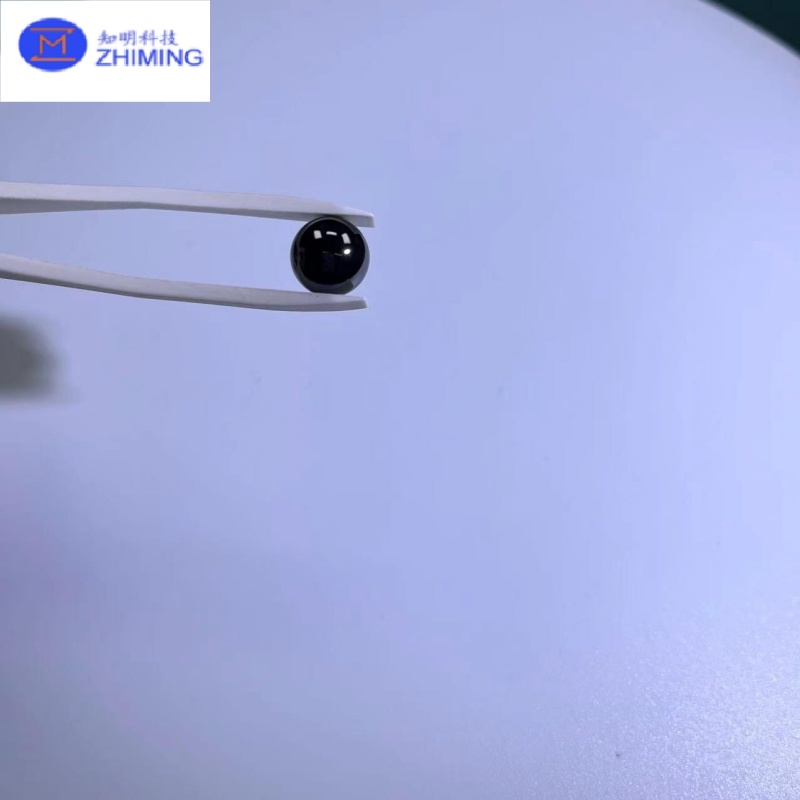

SiC Balls & Marbles (0.5mm–50mm) | Customizable High-Precision

Bearing Balls

Our silicon carbide (SiC) balls and marbles offer unmatched

hardness, thermal stability, and chemical resistance for

extreme-performance applications. Available in diameters from 0.5mm

to 50mm, these precision-grade spheres are fully customizable.

Ideal for high-speed bearings, semiconductor equipment, aerospace

mechanisms, and corrosive fluid systems, SiC balls outperform

steel, ceramic, and other materials in wear resistance, temperature

tolerance (up to 1950°C), and longevity.

Key Features

✔ Extreme Temperature Resistance – Stable in air (1600°C) and inert

gas (1950°C).

✔ Corrosion Proof – Resists acids, alkalis, and plasma erosion.

✔ Lightweight – Density 3.21 g/cm³ (60% lighter than steel),

reducing centrifugal forces.

✔ Precision Grades – Grade 5-10 (roundness ≤0.1μm, sphericity

≤0.15μm).

✔ Customizable – Adjustable size (±0.1μm), coatings (DLC), and

conductivity (N-doped).

Applications of SiC Ball

1. High-Speed Bearings

- Turbopumps (50,000+ RPM) – SiC’s lightweight and hardness prevent

deformation at extreme speeds.

- EV Motors – Electrically insulating variants eliminate arcing

risks.

2. Semiconductor & Vacuum Equipment

- EUV Lithography Stages – Particle-free, ultra-smooth surfaces (Ra

<0.02μm).

- Wafer Handling Robots – Chemical-resistant for cleanroom

environments.

3. Aerospace & Defense

- Satellite Mechanisms – Vacuum-compatible with zero outgassing.

- Jet Engine Components – Withstands 1,500°C exhaust heat.

4. Industrial & Chemical

- Valve Seals – Resists sulfuric acid, seawater, and high-pressure

fluids.

- Metering Pumps – Maintains precision flow control for abrasive

slurries.

5. Medical Devices

- Surgical Tools – Biocompatible and sterilizable (autoclavable).

- Dental Handpieces – No lubrication needed, reducing

contamination.

Specification

| Silicon Carbide Content | - | % | >99.5 |

| Average Grain Size | - | micron | 4-10 |

| Bulk Density | - | kg/dm^3 | >3.14 |

| Apparent Porosity | - | Vol % | <0.5 |

| Vickers Hardness | HV0.5 | Kg/mm^2 | 2800 |

| Modulus of Rupture (3 points) | 20°C | MPa | 450 |

| Compression Strength | 20°C | MPa | 3900 |

| Modulus of Elasticity | 20°C | GPa | 420 |

| Fracture Toughness | - | MPa/m^1/2 | 3.5 |

| Thermal Conductivity | 20°C | W(m*K) | 160 |

| Electrical Resistivity | 20°C | Ohm.cm | 10^6-10^8 |

| Coefficient of Thermal Expansion | a

(RT"800°C) | K^-1*10^-6 | 4.3 |

| Max. Application Temperature | Oxide Atmosphere | °C | 1600 |

| Max. Application Temperature | Inert Atmosphere | °C | 1950

|

FAQ

Q1: What’s the difference between SiC and silicon nitride (Si₃N₄)

balls?

- SiC: Harder (2800 HV vs. 1500 HV), higher temperature limit

(1950°C vs. 1200°C), but slightly more brittle.

- Si₃N₄: Better fracture toughness for high-impact applications.

Q2: What’s the lead time for custom orders?

- Standard sizes (1–10mm): 2–4 weeks.

- Custom sizes/tolerances: 4–6 weeks.