Wafer Bonding Equipment Room Temperature Bondin Hydrophilic Bonding

Si-SiC Si-Si Bonding 2 -12 inch

Wafer Bonding System Overview

Wafer Bonding Equipment is a high-end bonding equipment

specifically designed for silicon carbide (SiC) power device

manufacturing, supporting 2 to 12-inch wafer specifications. Wafer

Bonding Equipment incorporates advanced room-temperature direct

bonding and surface-activated bonding technologies, with special

optimization for SiC-SiC and SiC-Si heterogeneous bonding

processes. Featuring an integrated high-precision optical alignment

system (≤±2 μm) and closed-loop temperature/pressure control, it

ensures the high bonding strength (≥2 J/m²) and superior interface

uniformity required for power semiconductor device fabrication.

Wafer Bonding System Technical Specifications

Core Functional Parameters:

| Bonding Processes: | Supports direct bonding and plasma-activated bonding |

| Wafer Compatibility: | Full-range 2"-12" wafer handling |

| Material Combinations: | Si-SiC/SiC-SiC heterostructure bonding |

| Alignment System: | Ultra-high precision optical alignment (≤±0.5 μm) |

| Pressure Control: | Precision adjustable 0-10 MPa |

| Temperature Range: | RT-500°C (optional preheat/annealing module) |

| Vacuum Level: | Ultra-high vacuum environment (≤5×10⁻⁶ Torr) |

Intelligent Control System:

· Industrial-grade touch HMI

· ≥50 stored process recipes

· Real-time pressure-temperature closed-loop feedback

Safety Protection System:

· Triple interlock protection (pressure/temperature/vacuum)

· Emergency braking system

· Class 100 cleanroom compatibility

Extended Functions:

· Optional robotic wafer handling

· SECS/GEM communication protocol support

· Integrated inline inspection module

Wafer Bonding Equipment is specifically designed for R&D and

mass production of third-generation semiconductors. Wafer Bonding

Equipment modular architecture enables high-reliability bonding for

SiC-based power devices. The innovative plasma pretreatment

technology significantly enhances interfacial bonding strength (≥5

J/m²), while the ultra-high vacuum environment ensures

contaminant-free bonding interfaces. The intelligent

temperature-pressure control system, combined with submicron

alignment accuracy, provides wafer-level bonding solutions for

HEMT, SBD and other devices.

Photo

Compatible Materials

Applications

· MEMS Device Packaging: Wafer Bonding Equipment is suitable for

hermetic sealing of microelectromechanical systems (MEMS) such as

accelerometers and gyroscopes.

· CIS Image Sensors: Wafer Bonding Equipment enables

low-temperature bonding between CMOS wafers and optical glass

substrates.

· 3D IC Integration: Wafer Bonding Equipment supports

room-temperature stacking bonding for through-silicon via (TSV)

wafers.

· Compound Semiconductor Devices: Wafer Bonding Equipment

facilitates epitaxial layer transfer for GaN/SiC power devices.

· Biochip Fabrication: Wafer Bonding Equipment provides

low-temperature packaging solutions for microfluidic chips.

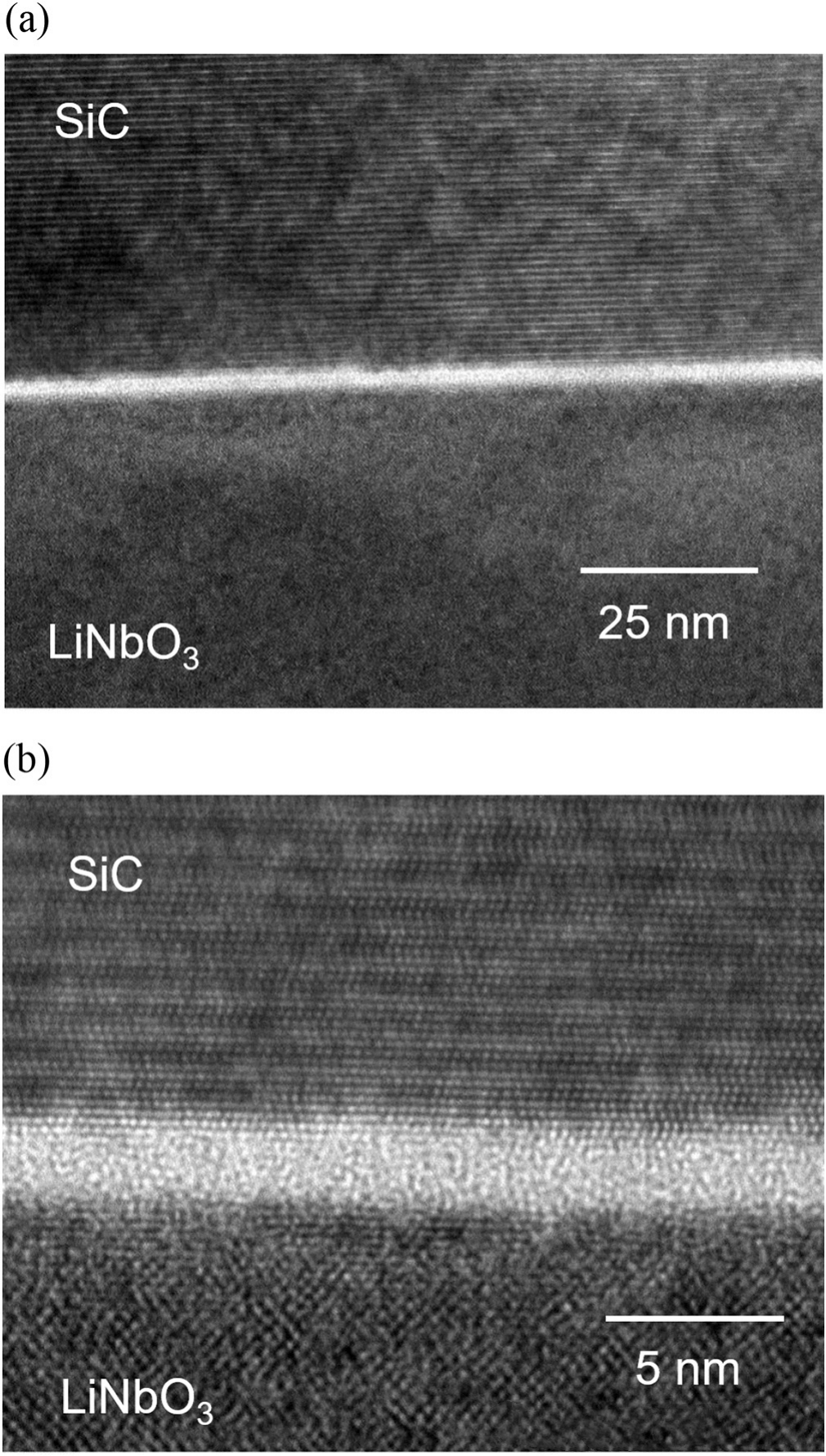

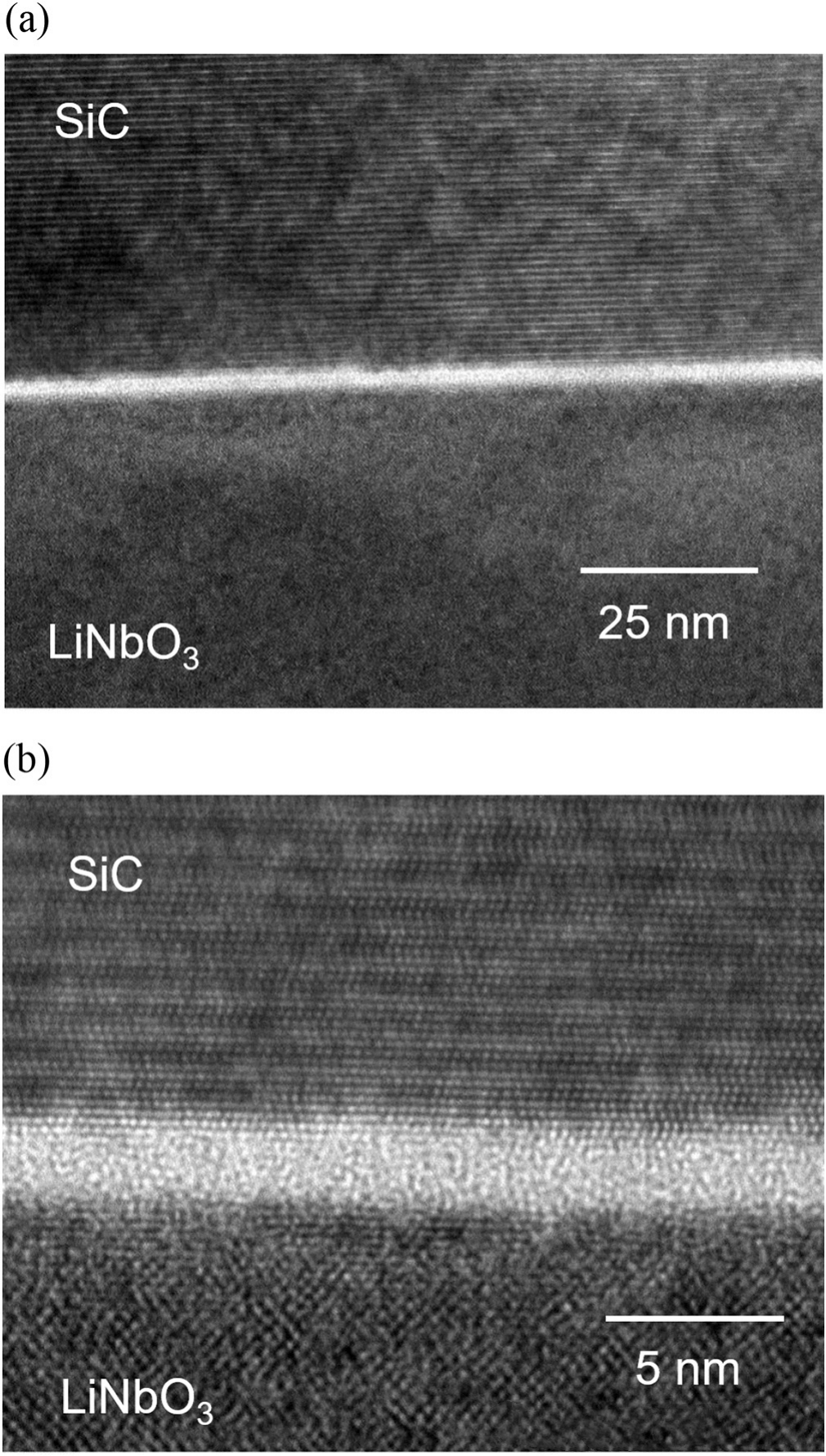

Machining effect——Bonding of LiNbO 3 wafer and SiC wafer

( (a) Photograph of LiNbO3/SiC wafers bonded at room temperature.

(b) Photograph of diced 1 × 1 mm chips. )

( (a) Cross-sectional TEM image of the LiNbO₃/SiC bonding interface

(b) Magnified view of (a) )