Microjet laser technology equipment wafer slice metal silicon

carbide material

Microjet Laser systems enable ultra-precision machining of

semiconductor materials by coupling high-energy pulsed lasers to

micron-scale liquid jets (usually deionized water or inert

liquids), using the guiding and cooling effects of the liquid jets.

With high precision, low damage and high cleanliness, microjet

laser technology is replacing traditional machining and dry laser

processes in the semiconductor field, especially in

third-generation semiconductors (SiC/GaN), 3D packaging and

ultra-thin wafer processing.

Microjet laser processing

Technical specifications

| Countertop volume | 300*300*150 | 400*400*200 |

| Linear axis XY | Linear motor. Linear motor | Linear motor. Linear motor |

| Linear axis Z | 150 | 200 |

| Positioning accuracy μm | +/-5 | +/-5 |

| Repeated positioning accuracy μm | +/-2 | +/-2 |

| Acceleration G | 1 | 0.29 |

| Numerical control | 3 axis /3+1 axis /3+2 axis | 3 axis /3+1 axis /3+2 axis |

| Numerical control type | DPSS Nd:YAG | DPSS Nd:YAG |

| Wavelength nm | 532/1064 | 532/1064 |

| Rated power W | 50/100/200 | 50/100/200 |

| Water jet | 40-100 | 40-100 |

| Nozzle pressure bar | 50-100 | 50-600 |

| Dimensions (machine tool) (width * length * height) mm | 1445*1944*2260 | 1700*1500*2120 |

| Size (control cabinet) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Weight (equipment) T | 2.5 | 3 |

| Weight (control cabinet) KG | 800 | 800 |

Processing capability | Surface roughness Ra≤1.6um Opening speed ≥1.25mm/s Circumference cutting ≥6mm/s Linear cutting speed ≥50mm/s | Surface roughness Ra≤1.2um Opening speed ≥1.25mm/s Circumference cutting ≥6mm/s Linear cutting speed ≥50mm/s |

For gallium nitride crystal, ultra-wide band gap semiconductor

materials (diamond/Gallium oxide), aerospace special materials,

LTCC carbon ceramic substrate, photovoltaic, scintillator crystal

and other materials processing. Note: Processing capacity varies depending on material

characteristics

|

Microjet laser equipment technical advantages

1. Small loss of processing materials and processing equipment

2. Greatly reduce grinding links

3. Low labor cost of automated processing

4. High quality machining wall and cutting edge

5. Clean processing without environmental pollution

6. High processing efficiency

7. High processing yield

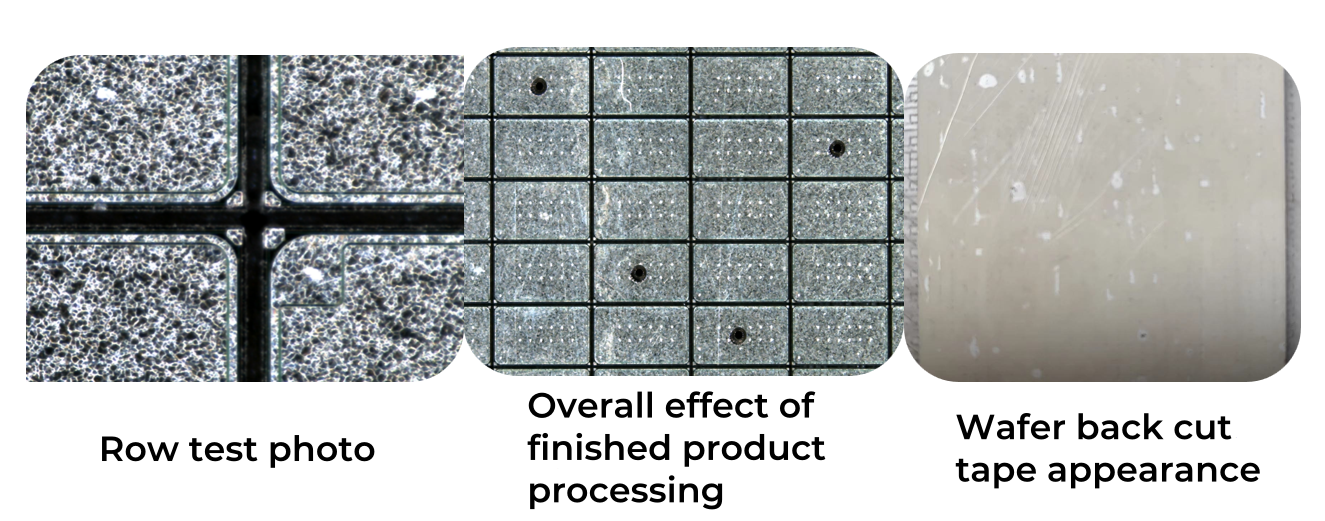

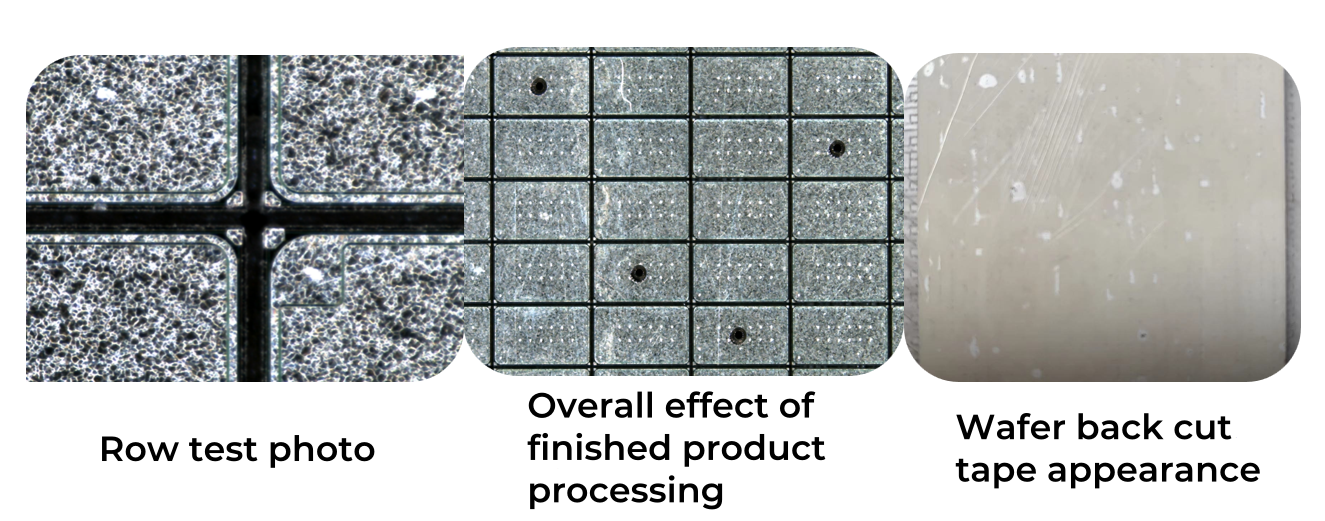

Microfluidic laser silicon wafer scribing

Test with the debugging processing parameters, and the cutting

effect is shown in the figure below. The cutting width of 40μm

nozzle is 35um; After the cutting is completed, the wafer is

completely scratched, and the back of the cutting tape (UV film) is

basically intact and not scratched through. There is no cracking

and crack on the edge of the crossing, which meets the processing

requirements.

Q&A