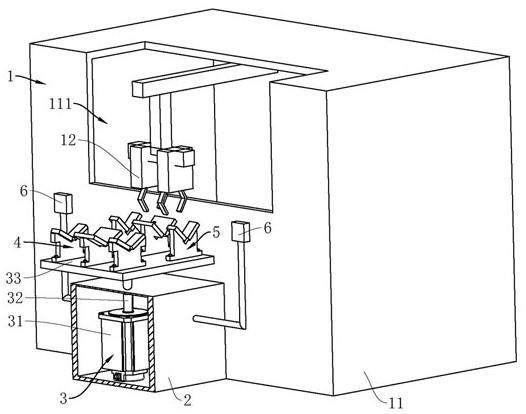

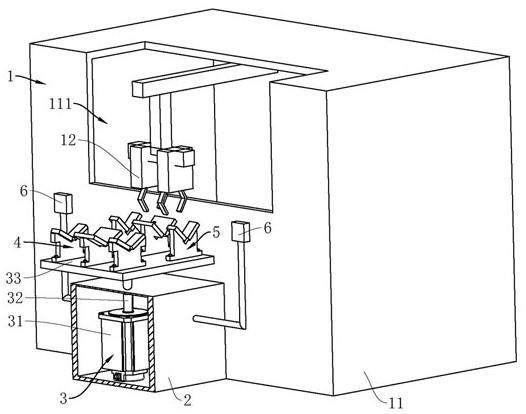

Monocrystalline silicon double station square machine 6/8/12 inch

burr ≤0.5mm high precision ±0.05mm

In the field of semiconductor materials processing, monocrystalline

silicon two-root vertical open-mechanism island building is a

highly specialized integrated production unit dedicated to

precisely cutting cylindrical monocrystalline silicon rods (Ingot)

into square or rectangular silicon blocks (Grit or Brick) in

preparation for subsequent slicing (such as making silicon wafers).

The core equipment is a two-root vertical cutting machine, and the

"manufacturing island" refers to the automatic and intelligent

processing system built around the equipment.

Core function

· Processing objects: monocrystalline silicon rods (usually Φ6

inches to Φ12 inches, 1-2 meters in length).

· Core task: Cutting four sides of a cylindrical silicon rod

vertically with a double saw blade to form a high-precision

square/rectangular silicon block (retaining the core and reducing

material waste).

· Key indicators: cutting accuracy (±0.05mm), surface flatness

(Ra≤0.5μm), edge breakage control (≤50μm).

Technical specifications

Technical parameters

| Name of parameter | Index value |

| Number of bars processed | 2 pieces/set |

| Processing bar length range | 100~950mm |

| Machining margin range | 166~233mm |

| Cutting speed | ≥40mm/min |

| Diamond wire speed | 0~35m/s |

| Diamond diameter | 0.30 mm or less |

| Linear consumption | 0.06 m/mm or less |

| Compatible round rod diameter | Finished square rod diameter +2mm, Ensure polishing pass rate |

| Cutting edge breakage control | Raw edge ≤0.5mm, No chipping, high surface quality |

| Arc length uniformity | Projection range <1.5mm, Except for silicon rod distortion |

| Machine dimensions (single machine) | 4800×3020×3660mm |

| Total rated power | 56kW |

| Dead weight of equipment | 12t |

Machining accuracy index table

| Precision item | Tolerance range |

| Square bar margin tolerance | ±0.15mm |

| Square bar edge range | ≤0.20mm |

| Angle on all sides of square rod | 90°±0.05° |

| Flatness of square rod | ≤0.15mm |

| Robot repeated positioning accuracy | ±0.05mm |

Design advantage

Stable performance:

1. Vertical cutting, silicon rod self-positioning;

2. Cutting head cutting wheel axle box hole integrated processing,

high precision, conducive to cutting;

3. Robot feeding and positioning, reliable and stable performance,

low maintenance cost;

Capacity 4 tons (square rod):

1. High cutting speed :≥40mm/min stable cutting feed:

2. Cut two silicon rods simultaneously;

3. Loading and unloading time ≤3min.

Low cost:

1. A robot can be configured with 2 hosts, which can be formed into

a rectangular manufacturing island unit, with flexible

configuration and low cost of single machine;

2. Workshop automation can use ground track conveying structure,

low automation cost.

High precision:

1. Root range ≤0.2mm;

2. The robot loading and unloading accuracy is high, repeated

positioning accuracy of ±0.05mm.

Technological advantage and development trend

Technical advantages:

High material utilization: By optimizing the cutting path, the

silicon block retention rate can reach more than 85% (traditional

methods are only 70%-75%).

Low damage processing: diamond wire sawing technology reduces

microscopic cracks and improves the yield of subsequent slices.

Intelligent production: Support unmanned operation, only 1-2 people

per shift monitoring.

Development trend:

Multi-line cutting technology: cutting with multiple diamond lines

at the same time to improve efficiency.

Digital twin: Optimize cutting parameters through virtual

simulation.

Green manufacturing: silicon powder recycling technology.

Q&A