Sapphire ky crystallization furnace kyropoulos foam process Large

size crystal growth equipment for LED substrate

Kyropoulos bubble method (Ky method for short) is a melt growth

method by dipping seed crystals into molten sapphire melt and

taking them out at a controlled rate when the crucible and crystal

are reversed, repeatedly adding layers to form crystals. This

method can grow high quality, low defect density, large size

sapphire crystal, and is widely used in LED substrate and other

fields.

Technical Parameter

| Melting amount: | ≥200kg |

| Furnace cavity height: | Φ800×1200mm |

| Single crystal pulling speed range: | 0.1 ~ 20mm/h stepless speed regulation |

| Fast rise/fall of seed crystal: | 0-150mm/min stepless speed regulation |

| Seed speed range: | 1 ~ 20r/min stepless speed regulation |

| Maximum lifting stroke of seed crystal shaft: | 400mm |

| Heater power: | 120KW |

| Maximum heating temperature: | 2100℃ |

| Power supply (incoming line) : | 3-phase 380V |

| Output working current: | 0-10000A DC |

| Output working voltage: | 0-12.5V DC |

| Maximum height of the host: | 2800mm |

| Limit vacuum of furnace chamber: | ≤6.7×10-3 Pa |

| Double load cell: | 100Kg(single) |

| Weight: | about 1500Kg |

| Machine weight: | about 2000Kg |

| Main machine area: | 3800×2100mm |

| The machine covers an area of: | 4000×3100mm |

| Inlet pressure: | 0.3MPa±0.02MPa |

| Water inlet temperature: | 20 ~ 25℃ |

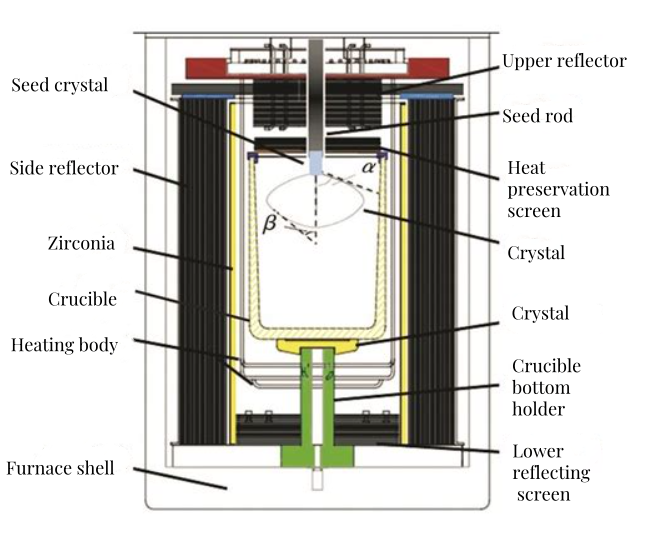

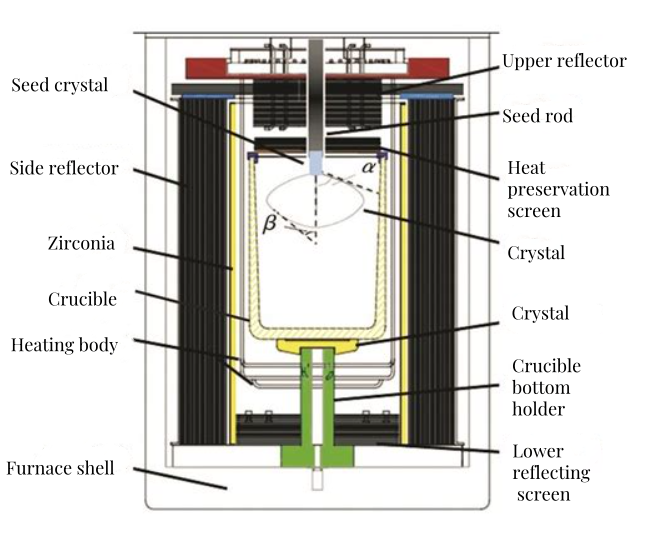

Working principle

The core of Kyropoulos method lies in thermal field design and seed

control. By heating the high purity aluminum oxide raw material in

the crucible, the equipment makes it melt and forms a temperature

distribution mode of high temperature in the upper part and low

temperature in the lower part. The seed crystals grow from the

center of the melt surface, with the seed crystals as the core, and

the melt crystallizes layer by layer from the crucible to the

crystal wall, finally forming a single crystal.

Product structure and characteristics

1. Thermal field design: including crucible, thermal protection layer, upper seed heat

exchanger and crucible support body, etc., to ensure uniform

crystallization of melt.

2. Seed crystal control: By precisely controlling the temperature gradient and pulling

speed of the seed crystal, high-quality crystal growth is achieved.

3. Automation system: Modern equipment is usually equipped with automatic planting

system and automatic control system, which can produce efficiently.

Technological advantage

1. High-quality crystal: Ky method can grow low defect density, large size sapphire

crystal, to meet the LED industry's demand for high-quality

substrate.

2. Relatively low cost: Compared with other methods (such as Czochralski method), Ky

method has low operational complexity and relatively controllable

cost.

3. Technological innovation: The improved Ky method (IKY) further improves the crystal yield

and reduces the production cost by optimizing the seed and neck

pulling technology.

Machine application

Kyropoulos bubble process equipment is widely used in the following

fields:

1. LED industry: Used to produce high-quality sapphire substrate to meet the needs

of LED chip manufacturing.

2. Infrared military devices: Sapphire is widely used in infrared window materials because of

its excellent optical properties.

3. Satellite space technology: Sapphire is used as a key material in satellite technology.

4. Laser window material: Used for high-performance laser window material.

Kyropoulos crystal growth equipment with its high efficiency, low

cost and high quality, in the field of sapphire crystal growth

occupies an important position, and is widely used in many

high-tech fields.

FAQ

1. Q: What are the core advantages of sapphire crystallization

furnace (Kyropoulos blister method) compared with other crystal

growth methods?

A: 1. No need to continuously pull the seed crystal: in the equal

diameter growth stage, the crystal is crystallized by natural

cooling, without relying on mechanical lifting, reducing mechanical

disturbances and defects.

2. Suitable for large size crystals: it can grow 85-120 kg sapphire

single crystal to meet industrial mass production needs, such as

LED substrate and optical window applications.

3. High yield and low defect: Optimized thermal field design (such

as segmented heaters and multi-layer heat shield), reduce

dislocation density (<1000/cm²), and yield more than 75%.

4. Energy saving and automation: fully enclosed vacuum chamber and

double-layer water cooling structure reduce energy loss, combined

with PLC control system to achieve automated operation and reduce

manual intervention.

2. Q: What is the essential difference between the working

principle of the bubble method equipment and the traditional

lifting method (such as Czochralski method)?

A: 1. Growth stage difference: lifting method: the whole process

needs to mechanically lift the seed crystal, and crystal growth is

achieved by controlling the lifting speed, which is easy to cause

defects due to mechanical vibration. Bubble growth method: only in

the necking stage to pull the seed crystal, the equal diameter

stage depends on the temperature gradient natural growth, reduce

stress and improve crystal uniformity.

2. Thermal field control: The bubble growth method adopts dual

temperature zone independent heating (side heating body + bottom

heating body), accurately regulates axial and radial temperature

gradients, and prevents bubbles and cracks. The lifting rule relies

on a single heating source, and the temperature gradient is fixed,

which is difficult to adapt to the growth of large crystals.

3. Application scenario: The bubble method is more suitable for

large size, high purity crystals (such as sapphire, calcium

fluoride), while the Tila method is mostly used for silicon,

germanium and other conventional semiconductor materials.

Tag: #Sapphire crystal furnace, #Kyropoulos bubble growth method,

#Ky growth equipment, #Sapphire crystal production, #Sapphire

wafer, #Large size crystal growth equipment, #LED substrate